Description

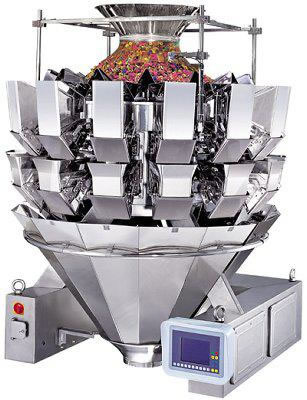

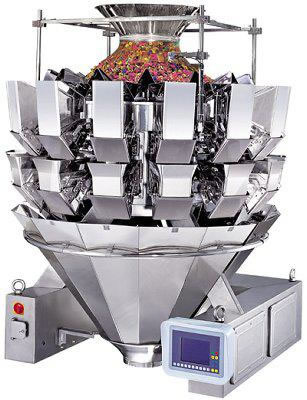

14-head electronic weighing packing system is capable of automatically finishing the whole packing process from feeding, measuring, filling, bag making, date printing, sealing, cutting, counting to conveying of finished products.

Bag Formats

Pillow Bag / Back Seal / Center Seal

Applications

14-head electronic weighing packing system is suitable to package small granular and hardware product requiring high accuracy, such as nails, puffed food, nuts, beans, chips, small hardware, candies, etc.

Payment terms

By T/T with 30% paid in advance and 70% balance paid before shipment.

Delivery terms

Deliver the 14-head electronic weighing packing system within 40 working days after receipt of the first deposit from the buyer.

Technical Parameters

Item

|

14-Head Electronic Weighing Packing System

|

Measuring Range

|

300 to 2500 g

|

Weight Accuracy

|

0.2 to 2 g

|

Weighing Speed

|

120 packs/min

|

Hopper Capacity

|

2.5 L

|

Drive System

|

Servo Motor

|

Power supply

|

AC 220 V/330 V 50/60 Hz, 2 kW

|

Dimension (mm)

|

1680 (L) x 1182 (W) x 1268 (H)

|

Weight

|

430 kg

|

Major Parts of 14-Head Electronic Weighing Packing System

1. Z type bucket elevator

2.14-head electronic combination weigher

3. Vertical packing machine

4. Supporting platform

5. Finished product conveyor

1. Z type buckets elevator

Features

1. It is used to deliver grain, food stuff, etc.

2. Conveyor with large conveying capacity, no crash material, high lifting, etc.

3. Lifting height: 3.3 to 10m (according to client’s requirements).

4. Lifting speed: 0 to 17 m/min.

5. Capacity: 5.5m3/hour.

Material

Spray printing (carbon steel) or 304 stainless steel (depends on client’s requirements).

2. 14-Head Electronic Combination Weigher

Applications

It is utilized to weigh granules, slices, rolls or materials with irregular shape, such as candies, seeds, jellies, fries, coffee granules, peanuts, puffy food, biscuits, chocolates, nuts, yogurt, pet food, frozen food, etc. It is also used to weigh small hardware and plastic components.

Salient Features

1. Amplitude can be adjusted freely and separately during running

2. More user-friendly.

3. Multi-language operating interface.

4. Compatible with Mouse, USB and SD card; 7 inch touch screen.

5. Asynchronously dropping material.

General Features

1. Carbon base with environmentally-friendly paint.

2. Design of third generation, inter-changeable AD card helps to maintain low cost.

3. Instant running statistics is conducive to easier commissioning of the weigher.

4. Different authority managements and more user-friendly.

5. Innovative and independent design of mother board and vibrator drive board.

6. HMI can be directly upgraded via USB flash disk.

3. Vertical Packing Machine

Features

1. Dual servo motor for film drawing down system.

2. Automatic film deviation rectifying function.

3. PLC controlled and pneumatic system for horizontal and vertical sealing.

4. When equipped with feeding and measuring equipment, it can complete the whole packing process form feeding, measuring, filling, sealing, date printing, charging (exhausting), counting to conveying of finished products.

5. Bag formats of pillow bag, gusset bag and stand-up bag are available according to client’s requirements.

4. Supporting Platform

Features

Supporting platform works with various kinds of vertical packing machine.

It is compact, stable and safe with guardrail and ladder.

It is used to support the weigher and used as accessorial equipment of the packaging system.

Dimension (mm): 2000 (L) × 2000 (W) × 1600 to 2400 (H)

Note: customized platforms and decks are perfect for increasing safety and line efficiency.

Material

The supporting platform body is fully made of 304# stainless steel.

5. Finished Product Conveyor

Features

1. Feeding Speed: 20 to 300 mm/s (adjustable).

2. Conveying Height: 0.8 m (height adjustable).

3. Power: 220 V, 50 Hz, 120 W.

Material

Spray printing (carbon steel) or 304 stainless steel (depends on client’s requirements).

Note: clients can choose some spray printing components and some 304 stainless steel components to form the automatic packing system. The price is flexible.